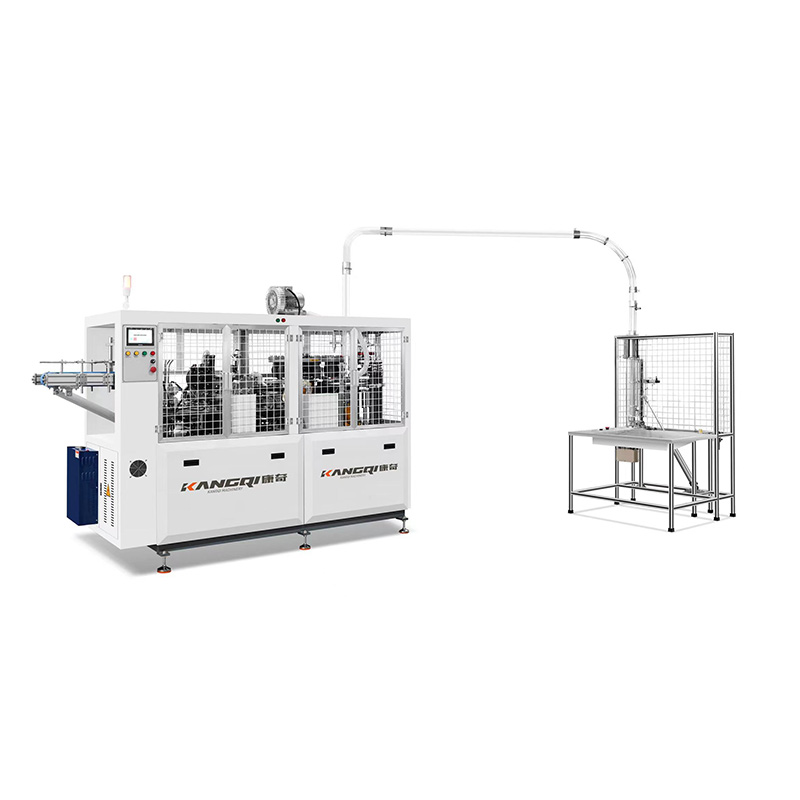

DPJ-A22型单盘纸杯成型机

发布日期:[2018-10-08] 点击率:| |

|

|

DPJ-A22型单盘纸杯成型机

1.纸杯规格:16-22盎司

2.纸杯材料 :单双面PE 淋膜纸(任意一种都可以)

3.纸张规格:210-380g/㎡

4.生产速度:55-65 pcs/min

5.电源:380V/220V 50Hz

6.总功率:6Kw

7.气源:0.4m3/min

8.重量:2200Kg

9.包装尺寸:2950 x 1150 x 1800mm

Technical Parameters:

1. Paper cup size: 16-22 ounces

2. Paper cup material: Single/double PE coated paper (both ok)

3. Paper raw material: 210-380g/㎡

4. Production speed: 55-65 pcs/min

5. Power supply: 380V/220V 50Hz

6. Total power: 6Kw

7. Gas source: 0.4m3/min

8. Weight: 2200Kg

9. Packing size: 2950 x 1150 x 1800mm

DPJ-A22型单盘纸杯成型机是由一个转盘完成纸杯成型,采用开放式间歇分度机构、链条传动、同步带传动、卷边采用单独升降结构、降低了主功能机构的行程、合理分布各个功能总成,使设备负载减轻。整机采用定时定量油脂润滑的方式,减低了机器零件的磨损;制杯过程PLC控制,采用光电传感器全程故障监控,步进电机送料(有杯片送料,没杯片不送料),从而提高设备性能,达到快速平稳运行,实现了故障自动停机,降低了工人劳动强度,提高了设备的稳定性。

The DPJ-A22 single-disc paper cup forming machine is formed by one turntable for paper cup forming. It adopts an open intermittent indexing mechanism, chain drive, and a separate lifting structure for the edge curling, which reduces the stroke of the main functional mechanism and rationally distributes the various functional assemblies. In this way, it reduces machine work load. The whole machine adopts the method of automatic lubrication of oil and grease to reduce the wearing of machine parts. This model is all controlled by PLC, with photoelectric sensor to detect fault automatically. The step motor control paper feeding(have paper then feeding, no paper, then no feeding). It improves the performance of the equipment, achieves fast and smooth operation, realize automatic shutdown of faults, reduce labor intensity, and improve equipment security and stability.

通过简化制杯工艺流程,送纸、粘合、上杯、送底、加热、卷底、滚花、卷口、卸杯、检测、自动计数收杯,是制作纸杯的不错选择。

By simplifying the cup making process, feeding, adhesive, cupping, bottoming, heating, bottoming, knurling, curling, unloading, inspection, and automatic counting. Our machine is best choices for making paper cups.

版权归w88优德官网所有